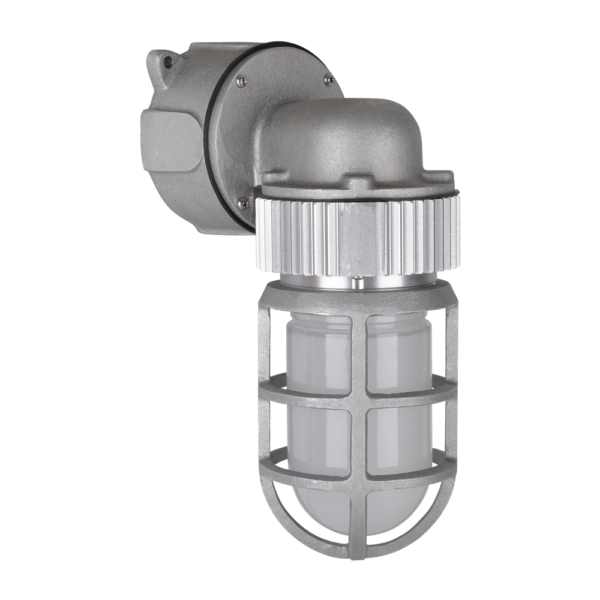

The Metallic LED VP Series by Phoenix Lighting is a high-performance marine and hazardous rated vapor proof fixture engineered for extreme environments. This versatile lighting solution delivers up to 1900 lumens while consuming only 17W, offering exceptional efficiency for industrial applications. Constructed with ultra-low copper content, marine grade aluminum housing, the fixture provides superior corrosion resistance and durability. The patented LED module is fully potted with optically clear silicone, creating a robust seal against water, debris, and dust ingress. Ideal for walkways, doorways, and perimeter lighting on marine vessels, large mining equipment, and industrial buildings exposed to harsh elements, the Metallic LED VP Series offers both ceiling and wall mounting options to suit diverse installation requirements.

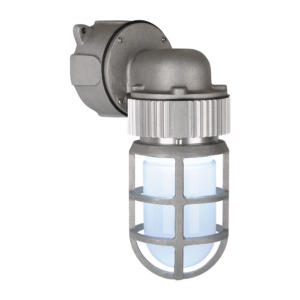

With an impressive 50,000-hour rated life, this fixture eliminates maintenance concerns while supporting green initiatives through its energy-efficient LED technology. The Metallic LED VP Series boasts comprehensive certifications, including UL/cUL for wet locations, marine outside type (saltwater) applications, and hazardous locations (Class I, Division II Groups A, B, C, D; Class II, Division II Groups F, G). Its IP66 rating ensures complete protection against dust and powerful water jets. Available in cool white (5600K) or warm white (3000K) color temperatures, the fixture comes standard with a heat-treated glass globe and guard, with optional polycarbonate prismatic globe and colored jelly jar-style globes available as accessories. The fixture operates on 100-277V AC power with standard 0-10V dimming capabilities and maintains functionality in extreme temperatures from -45°C to +40°C.

Reviews

There are no reviews yet