Color temperature plays a crucial role in industrial lighting design, directly impacting worker productivity, safety, and overall operational efficiency. This is especially important in explosion-proof environments where lighting must meet stringent safety requirements while providing optimal visibility. This comprehensive guide explores everything you need to know about color temperature for industrial applications.

Table of Contents

What is Color Temperature in Lighting?

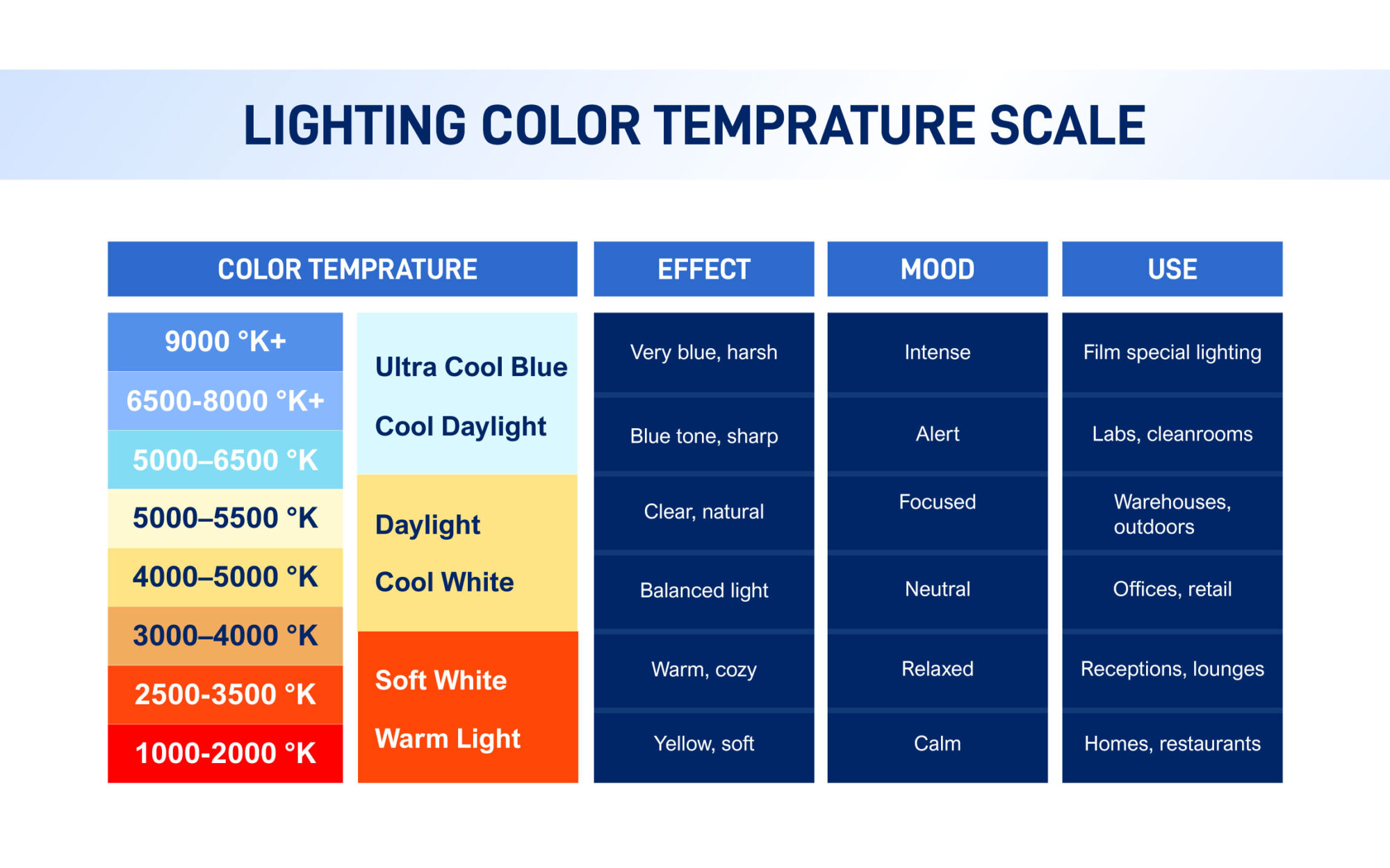

Color temperature refers to the appearance of light emitted by a bulb, measured in Kelvin (K). Lower Kelvin numbers (2700K-3000K) produce warm, yellowish light, while higher numbers (5000K-6500K) create cool, bluish light that mimics daylight.

In industrial settings, color temperature selection directly impacts:

- Worker alertness and productivity

- Visual acuity for detailed tasks

- Safety in hazardous environments

- Equipment maintenance and inspection capability

The Complete Color Temperature Chart for Industrial Applications

Understanding the different ranges of color temperature is essential for selecting appropriate lighting for various industrial environments:

Warm Light (2700K-3500K): Applications in Industrial Settings

This range produces a yellowish, warm light similar to traditional incandescent bulbs. In industrial settings, it’s typically used for:

- Break rooms and rest areas

- Security lighting where constant monitoring isn’t required

- Areas where a more relaxed atmosphere is desired

Neutral Light (3500K-4100K): Optimal Work Environments

This balanced range provides excellent illumination without being too harsh or too dim. Ideal applications include:

- General manufacturing floors

- Assembly areas with moderate detail work

- Warehouses and shipping areas

- Office spaces within industrial facilities

Cool White Light (4100K-5000K): Technical Areas

This crisper, whiter light improves contrast and visibility. Best used in:

- Quality control stations

- Technical repair departments

- Areas requiring moderate precision work

- Most manufacturing production lines

Daylight (5000K-6500K): Precision Work and Safety Applications

This bluish-white light most closely resembles daylight, providing maximum visibility. Recommended for:

- Detailed inspection areas

- Precision manufacturing

- Areas where color matching is critical

- High-hazard zones requiring maximum visibility

- Security monitoring stations

Color Temperature Considerations for Explosion-Proof Lighting

Explosion-proof lighting presents unique challenges and considerations when selecting color temperature:

Safety and Visibility Balance

In hazardous environments, the primary concern is always safety. Higher color temperatures (4100K-6500K) typically provide better visibility, which is crucial for:

- Identifying potential hazards quickly

- Reading safety information and warning labels

- Monitoring equipment status indicators

- Performing emergency procedures with precision

Recommended Color Temperatures for Hazardous Locations

For most explosion-proof applications, we recommend:

| Environment Type | Recommended Color Temperature | Reasoning |

|---|---|---|

| Class I (Gases, Vapors) | 5000K-6500K | Maximum visibility for gas detection and warning signs |

| Class II (Combustible Dust) | 4100K-5000K | Good contrast for dust accumulation visibility |

| Class III (Ignitable Fibers) | 4100K-5000K | Balanced visibility without excessive glare |

| Oil & Gas Processing | 5000K-6500K | Critical safety requirements demand maximum visibility |

| Chemical Manufacturing | 5000K-6500K | Color accuracy for chemical identification |

How to Select the Right Color Temperature for Your Industrial Environment

Choosing the optimal color temperature involves considering multiple factors specific to your facility:

Task Analysis

Begin by analyzing the primary tasks performed in the area:

- Detailed inspection work: 5000K-6500K

- General assembly: 4000K-5000K

- Warehouse and storage: 3500K-4000K

- Break areas and low-activity zones: 2700K-3500K

Environmental Factors

Consider environmental conditions that may impact lighting effectiveness:

- Areas with natural daylight: Match with 5000K-6500K for consistency

- 24-hour operation facilities: Consider circadian rhythm effects and potentially use variable CCT lighting

- Extreme temperature environments: Verify fixture performance specifications at the installation location’s temperature range

Safety Requirements

For explosion-proof and high-safety environments:

- Always prioritize visibility over aesthetic considerations

- Consider emergency lighting transition and consistency

- Ensure compliance with industry-specific regulations (API, OSHA, etc.)

Frequently Asked Questions About Industrial Lighting Color Temperature

What color temperature is best for industrial work environments?

For most industrial work environments, a color temperature between 4000K-5000K provides the optimal balance of comfort and visibility. This range offers a neutral to cool white light that enhances alertness and productivity while reducing eye strain during long shifts. For precision work or quality inspection areas, higher temperatures of 5000K-6500K are recommended.

How does color temperature affect worker productivity in industrial settings?

Color temperature significantly impacts worker productivity by influencing alertness, visual acuity, and comfort. Higher color temperatures (4000K-6500K) promote alertness and concentration, making them ideal for precision tasks and morning shifts. Studies show that properly matched color temperature to task requirements can increase productivity by 10-15% while reducing error rates. Additionally, appropriate color temperature can reduce eye strain and fatigue during long work periods.

What color temperature should explosion-proof lighting use?

Explosion-proof lighting typically performs best with color temperatures between 5000K-6500K. This higher color temperature range provides maximum visibility for safety-critical environments, enhancing the ability to read warning labels, identify potential hazards, and perform precise tasks in potentially dangerous areas. The bluish-white light at these temperatures most closely resembles daylight, providing optimal color rendering and contrast that can be critical in emergency situations.

Can color temperature affect safety in industrial environments?

Yes, color temperature directly impacts safety in industrial environments. Higher color temperatures (5000K-6500K) improve visibility of hazards, warning signs, and emergency equipment. This enhanced visibility can reduce accident rates by up to 60% compared to environments using inappropriate lighting. Additionally, proper color temperature helps maintain worker alertness during long shifts, reducing fatigue-related accidents, particularly during night operations.

Conclusion

Selecting the appropriate color temperature for industrial lighting, especially in explosion-proof applications, requires careful consideration of task requirements, environmental factors, and safety regulations. By understanding the Kelvin scale and its impact on visibility and performance, facility managers can create safer, more productive work environments while ensuring compliance with industry standards.

Need Help Selecting the Right Industrial Lighting Solution?

Our team of lighting experts specializes in explosion-proof and industrial lighting design. Contact us today for a customized lighting assessment tailored to your facility’s specific requirements.